Facilities & Laboratories

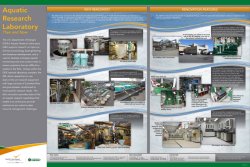

Aquatic Research Laboratory (ARL)

The Pacific Northwest National Laboratory (PNNL) operates the Aquatic Research Laboratory (ARL) that supports a variety of research on fish and other aquatic life, covering topics as diverse as toxicology, bioengineering, and biosensor development. Housed in PNNLs Life Sciences Laboratory in Richland, Washington, the laboratory is operated for the U.S. Department of Energy.

Columbia River and groundwater well water sources are delivered to the lab and conditioned to meet specific research needs. Inside the lab, temperature and lighting control are used to simulate seasonal and diurnal cycles. The lab is used for prototype aquatic tool development and to conduct tests to answer questions that are difficult to resolve in the field. These include toxicity testing, fish behavior studies, thermal stressors, tagging and tag life studies, bioenergetics, fish physiology, and modeling of biological systems.

The laboratory contains both indoor and outdoor facilities that are used for holding and acclimating test fish and supports specialized research equipment that can be installed and operated to meet specific research needs. Many species of cold- and warm-water fishes and invertebrates have been successfully reared and cultured for research projects. The ARL routinely acquires eggs and juvenile salmonids from various hatcheries and has the capacity to rear up to 60,000 fish for year round studies.

Research conducted at the ARL supports a variety of projects related to aquatic resource management challenges in the Pacific Northwest and elsewhere. These include:

- Effects of radiation on the Columbia River ecosystem

- Biological uptake, effects, and transport of contaminants

- Fish physiology and energetics in relation to water flow fields and shear/ turbulence

- Fish behavior in response to physical structure and flow

- Radio- and acoustic tag development and testing

- Egg and fry development in response to temperature and dissolved nitrogen gas

- Flow quantification and modeling

- New generation hydroturbine design

- Hyperbaric chamber testing to simulate turbine passage